-

首页 > Products > Three Axis Servo Robot >

- three-axis servo robot

three-axis servo robot

Brand :KEMANS

Product origin :GUANG DONG CHINA

Delivery time :15 Working days

Supply capacity :100 sets/month

1. Saving labor costs: The three-axis servo manipulator is mainly born to effectively reduce manual work. Therefore, after using the robot, the company can reduce the labor cost and reduce the labor cost, and can also complete various gravity work and Repetitive stacking operations. The labor force has limited working hours and the robot does not produce fatigue and can continue to work for a long time.

2. Improve work efficiency: The three-axis servo manipulator is an intelligent mechanical operation device and has various motion operation instructions. It can imitate various actions of manual operation, work with high precision and can complete a large workload. In particular, short-term work tasks can increase production on schedule. Improve the progress of the entire work and work efficiency for the enterprise to solve the problem of insufficient labor.

3. Reduced engineering accidents: There are certain risks in many mechanized work processes, and accidents may occur in case of accidental operation. The operation of the three-axis servo manipulator is set by program instructions and the operation and operation specifications, and the adaptability is strong to adapt to different working environments, whether it is oily or high temperature or corrosive working environment can adapt.

Product Description

Introduction of three-axis servo robot:

Applicable to the finished product and nozzle of each type of horizontal injection molding machine of 50~500 tons. The arm type is single-section type, which can be used to increase the jib for the three-piece mold, and at the same time clamp the finished product and the material head; the upper and lower strokes are driven by the cylinder from 700-1000mm. The horizontal axis standard is AC servo motor drive. The up and down and the lead are driven by the cylinder to increase the extraction efficiency in the mold. Installation of ZH series robots can increase production capacity (20%~30%), reduce product defect rate, ensure operator safety, reduce manual, precise control of production, and reduce waste. Widely used in electronic hardware, daily necessities, cosmetics, catering and household appliances industries, such as injection molding plastic parts, embedded in the mold (labeling, embedded metal, secondary molding, etc.)

Main specifications of three-axis servo robot:

| 基本参数COMMON APECIFICATIONS | ||||||||

| 电源power | 电源设备容量(KVA) Electric consumption | 较大消费电力(kw)max power consumption | 使用空气压力pressure | 驱动方式drive system | 气缸推力(气压为0.49mpa时)air cylinder driving force(air pressure at 0.19mpa) | 控制箱 box | ||

| 较大可搬重量(含夹具重) max load,incl.chuck weight | 姿势力矩posture torque | |||||||

| AC220V±10% 50/60HZ(单相) | 0.8 | 0.48 | 0.49mpa | 上下、前后:气缸 走行:AC伺服马达 | 5KG | 4.97N-m | 三六轴8寸触摸屏 | |

| 综合参数GENERAL APECIFICATIONS 根据参数的设定,较大可搬重量可能超过5kg/As per setting kf parameter,max.load may be over 5kg | ||||||||

| 机种Model | 行程(移动量)(mm) Stroke | 本体重量(kg) Net Weight | 空气消费量(NL/循环) Air Consumption(NL/cycle) | |||||

| 上下 Vertical | 上下 Vertical | 前后 Crosswise | 前后 Crosswise | 走行 Traverse | ||||

| KMSA-700IS3 | 700 | - | 100-720 | - | 1400 (1200) <1600> {1800} | 234 | 19.0 | |

| KMSA-800IS3 | 800 | - | - | 239 | 21.0 | |||

| KMSB-900IS3 | 900 | - | - | 244 | 23.0 | |||

| KMSB-1000IS3 | 1000 | - | - | 249 | 25.0 | |||

Product Application:

three-axis servo robot application advantages:

1. Saving labor costs: The three-axis servo manipulator is mainly born to effectively reduce manual work. Therefore, after using the robot, the company can reduce the labor cost and reduce the labor cost, and can also complete various gravity work and Repetitive stacking operations. The labor force has limited working hours and the robot does not produce fatigue and can continue to work for a long time.

2. Improve work efficiency: The three-axis servo manipulator is an intelligent mechanical operation device and has various motion operation instructions. It can imitate various actions of manual operation, work with high precision and can complete a large workload. In particular, short-term work tasks can increase production on schedule. Improve the progress of the entire work and work efficiency for the enterprise to solve the problem of insufficient labor.

3. Reduced engineering accidents: There are certain risks in many mechanized work processes, and accidents may occur in case of accidental operation. The operation of the three-axis servo manipulator is set by program instructions and the operation and operation specifications, and the adaptability is strong to adapt to different working environments, whether it is oily or high temperature or corrosive working environment can adapt.

Precautions for use three-axis servo robot:

1. When the external power supply is abnormal, the control system will be faulty. In order to make all the systems work safely, it is necessary to set the safety circuit outside the control system.

2. It is necessary to understand the contents of this manual before installation, wiring, operation, and protection. It is also necessary to be familiar with the mechanical, electronic knowledge and all relevant safety precautions when using.

3. Install on flame retardant materials such as metal and keep away from combustibles.

4. It is necessary to ground when using.

5. Wiring work must be carried out by a professional electrician.

Product service:

Pre-Sales Service

1. Your inquiry will be replied in 24 hours

2.Inquiry and consulting support.

3. View our Factory.

After-Sales Service

1. The company adopts the whole-sale online tracking after-sales service method for the products it supplies.

2. The warranty period shall be calculated from the date of installation and commissioning of the equipment and the acceptance of both parties, except for the wearing parts and the operating system and software.

3. Failure caused by human factors or improper operation and natural disasters and irresistible human factors are not covered by the warranty.

5. Establish installation, daily maintenance and maintenance service files, and record the use, maintenance and maintenance of the equipment in detail.

6. Regularly return online or online to solve specific problems encountered during the operation of the equipment, and prevent problems before they occur.

7. Provide technical training for complete equipment use, simple maintenance and maintenance.

8. After the warranty period, the company will charge the repair cost of the parts below the market sales price and provide comprehensive services for life;

We will comprehensively consider the after-sales service of the equipment in terms of management and technology, and provide comprehensive protection for the system with fewer problems and no problems.

9. Warranty period: The problem with the equipment is solved first by online. If it can't be solved online, then our factory will send personnel to the scene to solve.

10. The response time is as follows: (If we need to send staff to the site for maintenance, our factory will immediately start after receiving the notice)

(1), the first level of failure is repaired within 24 hours.

(2), the secondary fault is repaired within 12 hours.

(3), the third-level fault is repaired within 8 hours.

(4) The repair response time does not include the travel time.

11. The fault levels are classified as follows:

(1), one-level failure: the entire system equipment is caused by the failure;

(2), secondary fault: the system equipment is seriously affected due to the fault;

(3), three-level fault: the efficiency of the system equipment is affected by the fault, but the equipment can still operate.

Packing & Delivery

The normal package is wooden box(Size: L*W*H). If export to european countries,the wooden box will be fumigated.If container is too tigher,we will use pe film for packing or pack it according to customers special request.

The package size is customized according to the size of the goods

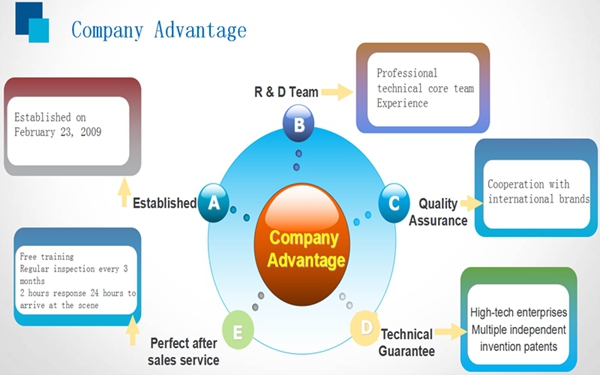

Our Company:

KEMANS is a China based high tech company established in 2009, focusing on manufacturing of take out robot arm for plastic injection molding machine and factory automation system. For over 10 years, KEMANS is specialized in research and development, productio n sales and services of take out robots such as three axis servo robots,five axis servo robots, swing arm take out robots,customized industrial robot,X beam linear servo driven robots,longitudinal 3/5 axis AC servo driven robots, swing arm robot,sprue picker.etc.Through hard work and dedication, we are now one of the market leaders of robot arm manufacturer and total solution provider in China.

n sales and services of take out robots such as three axis servo robots,five axis servo robots, swing arm take out robots,customized industrial robot,X beam linear servo driven robots,longitudinal 3/5 axis AC servo driven robots, swing arm robot,sprue picker.etc.Through hard work and dedication, we are now one of the market leaders of robot arm manufacturer and total solution provider in China.

With our dedicated management and outstanding technical research and development team, we strive for constant innovations to create values for our partners. Our global network and experienced service teams are committed to help our partners reaching new heights in their respective industries.

FAQ

Q: Are you trading company or manufacturer ?

A: We are a professional manufacturer. We are warmly welcome clients from worldwide to visit our factory and cooperate with us.

Q: How long is your delivery time?

A: Generally it is 15-20 days if the goods are in stock. or it is 20-30 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: No. Customers can visit our factory and view samples.

Q: What is your terms of payment ?

A: 50% T/T in advance. balance before shippment.

If you have another question, pls feel free to contact us.

WHY CHOOSE US?

1.The robot arm can be labeled as specified by the customer.

2.Color can follow the requirements of customers.

3.The consignee and consignor on the B/L can be decided by the customer.

4.Follow the principle of mutual benefit, all prices can be accommodated.

5.If you intend to wholesale manipulator, then please find me, wholesale prices are very attractive.